Layout Services

Leading of Column Layout, Layout Survey and Factory Layout from Lucknow.

Column Layout – Precision Positioning for Structural Stability

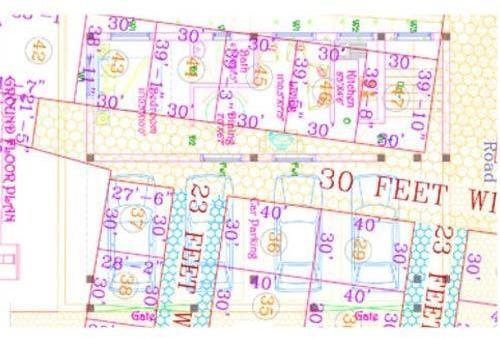

Column Layout is a critical stage in building construction, defining the exact positioning of columns on-site according to the structural design. Columns form the backbone of any building, carrying loads from slabs and beams down to the foundation. Accurate column layout ensures structural stability, proper alignment, and seamless construction execution.

Professional surveyors and engineers use advanced instruments such as Total Station, Auto Level, and GPS equipment to transfer the column grid from structural drawings to the ground with millimeter accuracy. The layout involves marking the center points of columns, ensuring alignment with the architectural plan, and cross-checking measurements to avoid errors during construction.

Key Importance of Column Layout:

- Structural Accuracy: Ensures columns are placed at the correct location and spacing.

- Load Distribution: Guarantees proper transfer of loads to the foundation.

- Error Prevention: Avoids misalignment that can lead to structural defects.

- Construction Efficiency: Provides clear reference points for masons and contractors.

- Compliance with Design: Matches the approved architectural and structural plans.

Column layouts are essential in residential buildings, commercial complexes, industrial structures, and high-rise projects .Even a small error in marking columns can result in costly rework, safety risks, and project delays. Precision and professional expertise are crucial for successful execution.

Layout Survey – Accurate On-Site Transfer of Plans

Layout Survey is an essential step in land development and construction projects, involving the accurate transfer of approved building or site plans onto the ground. It ensures that plots, roads, utilities, and structures are positioned exactly as per the architectural and engineering drawings. Layout surveys serve as the foundation for **error-free construction, legal compliance, and efficient land utilization.

Using advanced surveying instruments like Total Station, DGPS, Auto Level, and GPS equipment, professional surveyors mark reference points, grid lines, and dimensions on-site with high accuracy. The process includes boundary verification, alignment checks, and positioning of columns, foundations, and utilities, ensuring that the development matches approved designs.

Key Applications of Layout Surveys:

- Residential & Commercial Layouts: Marking plots, roads, and open spaces.

- Townships & Housing Projects: Ensuring proper division of land as per authority approvals.

- Industrial & Institutional Projects: Positioning structures and utilities with precision.

- Construction Works: Transferring grid lines for columns, foundations, and walls.

- Government Compliance: Meeting standards set by municipal and development authorities.

A layout survey prevents misalignment, boundary disputes, and construction errors saving both time and cost. It also provides developers with accurate site records, which help in property sales, approvals, and long-term project management.

Whether for real estate plotting, township planning, or commercial and industrial development, hiring a professional Layout Surveyor ensures accuracy, transparency, and smooth execution**.

Factory Layout – Efficient Industrial Planning

Factory Layout refers to the strategic planning and arrangement of machinery, equipment, storage areas, utilities, and workstations within an industrial site. The main purpose of an efficient factory layout is to ensure smooth workflow, safety, reduced production costs, and higher productivity. Proper layout design also optimizes space utilization, minimizes material handling, and helps industries meet operational and safety standards.

Professional factory layout planning is carried out using modern tools like CAD design, Total Station survey, GPS/DGPS, and GIS mapping, ensuring accuracy and compliance with industrial norms. The process involves studying site conditions, production processes, manpower requirements, and safety regulations, followed by creating a practical layout plan that balances efficiency and flexibility.

Key Benefits of a Factory Layout:

- Efficient Workflow: Smooth movement of raw materials, semi-finished, and finished goods.

- Space Optimization: Maximum utilization of land and built-up areas.

- Worker Safety: Adequate spacing, ventilation, and emergency exits.

- Cost Reduction: Minimizes unnecessary material handling and idle time.

- Future Expansion: Flexible layouts allow scaling of operations.